WOOD.PROTECTOR on the test bench

Deutsch // English

Splitting of the ends is usually caused by uneven drying of the wood. Inside every tree, vascular bundles provide nutrition and water from roots to the top. The cutting of these tubes at the front and end of logs and lumbers enables enhanced water evaporation which leads to faster drying. Furthermore, these uneven drying leads to internal tensions which cause the splitting of the wood at the ends.

This can be prevented though application of an appropriate wood protection agent, which adjusts the water-permeability of the coated front to become equal to the evaporation rate (drying velocity) of the rest of the wood.

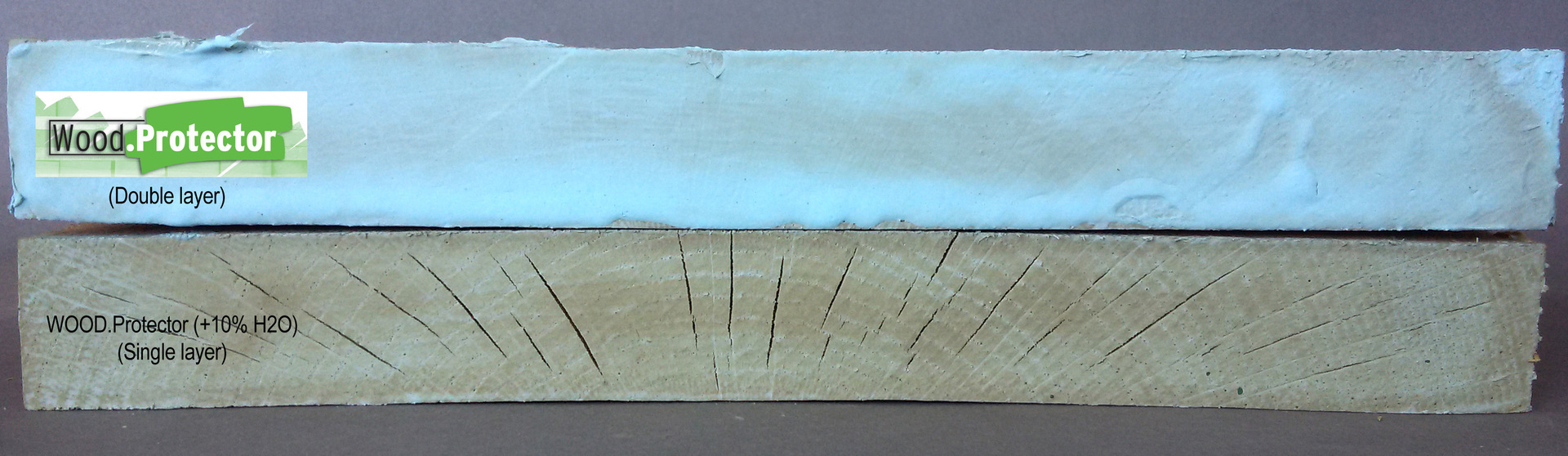

Correct applied Wood.Protector ensures an even drying process and guarantees protection from splitting of the ends, as it can clearly be seen in the figures below.

Experimental design

Oak wood samples (25x180mm; fresh sawn!) were exposed to extreme conditions (Dry kiln +40°C) for 48 hours.

Sequence of the pictures / samples: top down

Sample 1: Wood.Protector undiluted / double layer

Sample 2: Wood.Protector diluted with 10% H2O/ single layer

Sample 3: Control (Backside of sample 1)

Sample 4: Control (Backside of sample 2)

Results: In comparison to unprotected wood and wood with misapplied protection agent, wood protected with Wood.Protector applied in a correct (appropriate) manner, shows that cracks of the front can be avoided, even under extreme conditions!

Experimental design

Oak wood ends with a single layer of Wood.Protector (above: Wood.Protector yellow; below: Wood.Protector blue; center: control / without protection). The samples were exposed to continuously hot airstream over a period of 2,5 hours. Pictures were taken in intervals of 10 minutes. Initial cracks could be seen in the unprotected control after 50 minutes of exposure. No obvious cracking could be seen on fronts of logs which were protected with Wood.Protector. Note: Only for illustrative purposes. Experimental conditions are artificial and cannot be compared to conventional drying.

Use the control panel to start the clip, increase the size or select single pictures.